Static electricity is a kind of accumulated charge which is a result of an imbalance of electrons and protons. Rubbing two materials together may slough off an atom or two as they touch with each other. This creates an imbalance in one of the materials, which sits there waiting for an opportunity to balance itself when something with a corresponding imbalance comes close enough. The balancing discharge causes a pop of electricity or a static discharge. Because this voltage is just there, it is called static. As it seeks to move to something else, the movement classifies it as current electricity, and no longer static.

Why is static electricity harmful in special occasions?

Static electricity in the wrong environments, however, may be harmful or even fatal. Some locations must eliminate these little charges without excuses. Agricultural businesses, such as grain storehouses, accumulate dust which is easily ignited by a spark. The resulting explosions are fatal. Another danger is that the actual movement of the grains as they are transported from truck to silo can accumulate a static charge. This sort of buildup is usually thought out and the equipment is well grounded, but the transient sparks from other sources can be very explosive. Power tools are usually prohibited in these areas.

Pharmaceutical plants, manufacturing facilities, and other factories using chemicals and gases which are explosive should protect themselves from explosions. These places usually have required grounding of any moving item to eliminate static build-up, and tools are also closely monitored or prohibited.

What does Weston do to eliminate static electricity to keep relative workers safe?

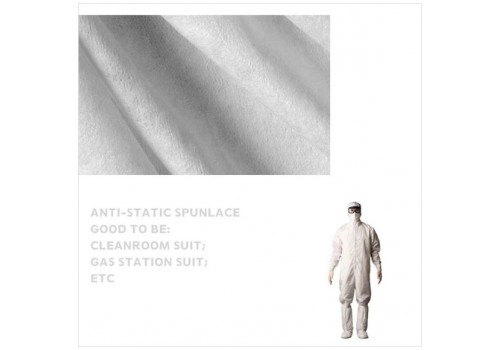

Polyester can be static before treatment. When we produce spunlace, by forming a nonwoven web from a thermoplastic mixture of an antistatic agent and a thermoplastic polyester fiber, the non woven web having improved antistatic properties as well as alcohol repellency properties is generally provided. A higher energy treatment is applied by us to the surface of the nonwoven webbing. Then, a fluorinated agent is added to the surface of the spunlace web utilizing a monomer deposition process. The monomer deposition process can generally include evaporating a liquid fluorinated agent in a vacuum chamber, followed by depositing the fluorinated agent gas on a surface of the spunlace web, and exposing the surface to radiation. All these technics will make the polyester spunlace into a more efficiency barrier against of static electricity.

Anti-static Polyester Spunlace

- รหัส/รุ่น: Anti-static Polyester Spunlace

- สถานะสินค้า: มีสินค้า

-

3,570.00 บาท

- ราคาไม่รวมภาษี: 3,570.00 บาท

คำค้น: Anti-static Polyester Spunlace, Anti-static Spunlace, Polyester Spunlace, Spunlace